Blister Packing Machine for Liquid

Basic Info

Model No.: DPP-80 liquid

Product Description

Model NO.: DPP-80 liquid Application: Cosmetics, Dairy Products, Tablet, Medicine, Pills Forming Species: Blister Forming Driven Type: Electric Packaging: Aluminum Plastic Sheet Name: Blister Packing Machine Construction Material: Stainless Steel Speed: 2400sheet/Hour Model Standard: 80*57mm PVC: 0.15-0.5*110mm Trademark: YD Specification: CE, SGS, ISO, GMP HS Code: 84223030 Automatic Grade: Automatic Type: Filling and Sealing Machine Forming Function: Forming and Sealing Material Type: Solid Packaging Material: Plastic Other Name: Liquid Packing Machine Purpose: Liquid Packing Power: 0.75kw Max. Area: 105*70mm Ptp: 0.02-0.035*110mm Transport Package: Wooden Case Origin: China DPP-80

DPP-80Liquid Blister Packaging Machine Features:It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

Features:It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

2. Imported controlling system is adopted; also it can be equipped with detecting and rejection function device for number of medicines according to the user's requirement.

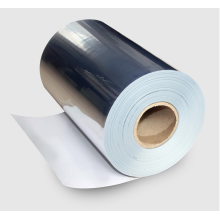

3,It adopts photoelectrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

4, It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.

5,The machine is suitable for industries of foodstuff, medicine, medical instruments, hardware, electronics and etc for packing.

Technical Specificatio

Work process Forming ( up and down heating) Heating Sealing ( up heating) Embossing Impression Cutter Finished product output

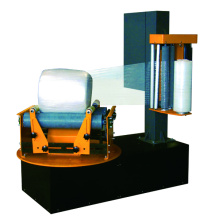

Sample picture:

Electrical components:

Contact us if you need more details on Liquid Packing Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Liquid Blister Packing Machine、Liquid Filling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

DPP-80Liquid Blister Packaging Machine

Features:It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided.

Features:It adopts the newest type high-power transmission mechanism to arrange the chain and drive the main driving shaft. The errors and noises of other gear wheel transmission can be avoided. 2. Imported controlling system is adopted; also it can be equipped with detecting and rejection function device for number of medicines according to the user's requirement.

3,It adopts photoelectrical controlling system to make PVC, PTP, Aluminum/Aluminum material to be automatically fed and waste side to be cut automatically to guarantee the Synchronous stability of over- length distance and multi stations.

4, It can be optional equipped with photocell correction device, imported stepper motor traction and image- character register to optimize packing grade.

5,The machine is suitable for industries of foodstuff, medicine, medical instruments, hardware, electronics and etc for packing.

Technical Specificatio

| Model | DPP-80 |

| Punch frequency | 10-33times/min |

| Production capacity | 2400plates/hour |

| Max. Forming area & Depth | 105x70(standard depth <=15mm), Max. Depth 25mm( As adjusted |

| Standard Stroke range | 30-80mm(can be designed as per user's required) |

| Standard plate size | 80x70mm (can be designed as per user's required) |

| Air pressure | 0.4-0.6Mpa |

| Compressed air required | ≥0.3m3/min Air compressor≥0.3m3/min |

| Total power supply | 380V/220V 50Hz 2.8Kw |

| Main motor | 0.75Kw |

| PVC hard Film | 0.15-0.5*110(mm) 0.15-0.5*110 (mm) |

| PTP Aluminum film | 0.02-0.035*110(mm) 0.02-0.035*110 (mm) |

| Dialysis Paper | 50-100g*110(mm) 50-100g*110(mm) |

| Mould cooling | Tap water or Recycling water |

| Overall Dimension | 1840x590x1100(mm)(LxWxH) 1840x590x1100 (mm)(LxWxH) |

| Weight | Net 450kg Gross weight: 520kg |

| Noise index | <75dBA |

Sample picture:

Electrical components:

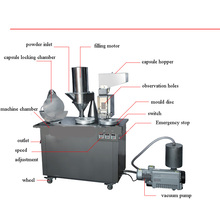

| DPP Standard configuration list of DPP-80 Liquid Blister packing machine | |||||

| Item | Name | Spec./Model | Brand | Qty | |

| 1 | Traction Cylinder | SSAφ32×15 | Kaogeer | 2 | |

| 2 | Main Motor | YS750W-4R | Zhejiang Taibang | 1 | |

| 3 | Forming heating plate | 130×110×22 | Zhejiang hongxing | 2 | |

| 4 | Heating sealing plate | 115×80×22 | Zhejiang hongxing | 1 | |

| 5 | Frequency inverter | DVA-2S0007G | Zhejiang delaier | 1 | |

| 6 | Material Feeding motor | 70-CK-25-K | Zhejiang Maili | 1 | |

| 7 | Thermocouple | TES-2M | Tes Taiwan | 2 | |

| 8 | Air circuit breaker | C65N-20A/2P | Schneider | 1 | |

| 9 | Air circuit breaker | C65N-6A/1P | Schneider | 2 | |

| 10 | Air circuit breaker | C65N-10A/1P | Schneider | 1 | |

| 11 | Relay | HRS4H-S | HKE | 5 | |

| 12 | PC control panel | / | Wenzhou Tuanjie | 1 | |

| 13 | Solid relay | SSR-40DA | Taiwan Forke | 2 | |

| 14 | Control transformer | JBK3-63 | Zhejiang Chint | 1 | |

| 15 | Electromagnetic Valve | SG4V210-08 | AirTAC | 3 | |

| 16 | Emergency button | XB2-BS542 | Schneider | 1 | |

| 17 | Photoelectric sensor | J12-A4JK | BDL | 3 | |

Contact us if you need more details on Liquid Packing Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Liquid Blister Packing Machine、Liquid Filling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Feeding & Packing Machine

Premium Related Products

Other Products

Hot Products

GMP Standard Tablet Coating Machine for PharmaceuticalRotary Tablet Press Machine (ZP-9) for PillStainless Steel Grinder/ Pin MillV Shape Mixer for Two Powder MaterialFluid Bed Granulating Machine for MedicineGMP Standard Stainless Steel Tray Drying MachineGlass Type Lab Scale Mini Spray DryerMc-1 Bag FilterJyg Paddle DryerSzg Cone Vacuum DryerZlg Vibration Fluid Bed DryerHyg Rotary DryerStainless Steel 304 Spin Flash Dryer for Chemical ProductLPG Centrifugal Spray DryerDw Belt DryerCT-C Hot Air Circulation Oven