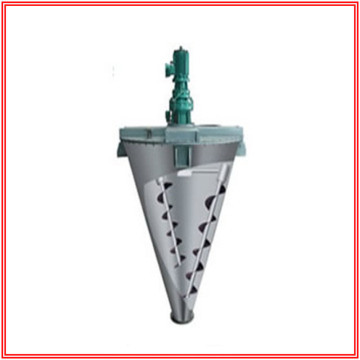

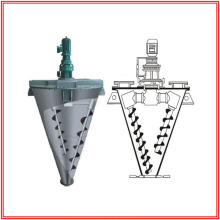

Verticle Nauta Mixer for Powder

Basic Info

Model No.: DSH

Product Description

Model NO.: DSH

Working: Shear Mixer

Application: Powder, Granules

Application Area: Chemical

Mixing Drum Shape: Conical

Operating type: Cycle Operating

Filed of Application: Chemical, Food Powder

Working Cycle: 5-20minutes

Spiral: Double Spiral

Control: Automatic Control

Electricity: 220V 380V 400V 440V

Trademark: CK

Origin: China

Mixer Type: Screw Mixer

Stirring Type: Spiral

Certification: CE, ISO, GOST, SONCAP, UL, CCC, API

Layout Type: Verticle

Additional Capabilities: Milling

Condition: New

Structure: Conical Tank

Screw: Double Screw

Discharge: From Bottom

Power: 5-40kw

Certificate: Ce SGS

Specification: CE ISO

HS Code: 84223030

First, screw/ spiral mixer application:

This machine is widely used in chemical, fertilizer, oil fields, oil refineries, pesticides, veterinary drugs, paints, pigments, dyes, metallurgy, metallurgy, refractory, mining, building materials, electronics, plastics, feed, aquaculture, pharmaceutical, biotechnology, food, solid health care products, ceramics, glass and new materials, nuclear materials, and many other industries - solid mixing, solid - liquid mixing, liquid - liquid mixing. The machine wide adaptability mixture, mixing heat-sensitive materials composition does not produce segregation phenomenon of mixed coarse, fine and ultra-fine powder of various particles, fibers or sheet material has good adaptability .

Second, the principle:

Rapid rotation mixer consists of two asymmetric spiral sheet material upward, forming two shares asymmetric tube arm from the bottom up along the spiral stream. Boom driven spiral revolution, so that different degrees of material into the spiral outer envelope of the stud. Part of the material are staggered lift, another part of the material was thrown stud, so as to constantly update the proliferation of full-circle orientation materials, be referred to the upper portion of the material in the two strands converge toward the center of the pocket formed generally downward stream, supplement bottom of the hole, so as to form convection circulation. Due to the complexity of the motion, the material in a relatively short time to obtain a homogeneous mix, a higher degree of mixing.

| spec. | unit | DSH0.3 | DSH0.5 | DSH1 | DSH2 | DSH4 | DSH6 | DSH10 |

| total volume | (m3) | 0.3 | 0.5 | 1 | 2 | 4 | 6 | 10 |

| feeding rate | 0.4-0.6 | |||||||

| diameter of materials to be mixed | (um) 40-3000 | |||||||

| operation condition | Ambient temperature,normal pressure,sealed to dust | |||||||

| production capacity p=1g/cm3 | (kg) | 180 | 300 | 600 | 1200 | 2400 | 3600 | 6000 |

| power | (kw) | 2.2 | 2.2 | 5.5 | 5.5 | 11 | 20.7 | 30.7 |

| time of mixing | (min) 4-10(special material to be determined by trial) | |||||||

| weight | (kg) | 500 | 1000 | 1200 | 1500 | 2800 | 3500 | 4500 |

Contact us if you need more details on Mixer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Nauta Mixer、Spiral Mixer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Powder Mixers

Other Products

Hot Products

GMP Standard Tablet Coating Machine for PharmaceuticalRotary Tablet Press Machine (ZP-9) for PillStainless Steel Grinder/ Pin MillV Shape Mixer for Two Powder MaterialFluid Bed Granulating Machine for MedicineGMP Standard Stainless Steel Tray Drying MachineGlass Type Lab Scale Mini Spray DryerMc-1 Bag FilterJyg Paddle DryerSzg Cone Vacuum DryerZlg Vibration Fluid Bed DryerHyg Rotary DryerStainless Steel 304 Spin Flash Dryer for Chemical ProductLPG Centrifugal Spray DryerDw Belt DryerCT-C Hot Air Circulation Oven