CT-C Hot Air Circulation Oven

Basic Info

Model No.: CT-C

Product Description

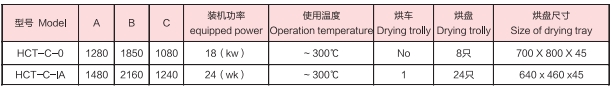

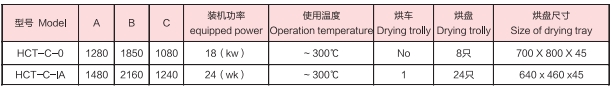

Model NO.: CT-C Heating Mode: Steam or Electricity Operation Pressure: Atmospheric Dryer Structure: Oven Sprayer: Air-Flowing Type Type of Atomization: Hot Air Circulation Transport Package: Foam Origin: Changzhou, China Movement Way: Combined Drying Medium: Air, Air Operational Method: Intermittent Type of Flow: Parallel Flow Appearance of Dried Sample: Powder, Granule, Paste, Sheets Trademark: Changzhou Fanqun Specification: CE HS Code: 841939909 About CT-C Hot Air Circulation Oven

Hot air circulation oven includes four parts: main chamber, recycle fan, heating system and control system. Materials will be put on the drying tray and be pushed into the drying chamber by trolley. Cold air will be heated to a certain temperature via heating device, under the working of recirculation fan, hot air recycles in chamber, thus drying purpose could be reached by fully contacting between hot air and material. During drying, humid air will be exhausted gradually through damp outlet. Meanwhile, fresh air will be supplemented. Temperature inside oven could be kept evenly by adjusting the angle of shutter, thus make sure the drying uniformity of material with equal rate.

Features

- Most of hot air is circled inside the oven. The hot efficiency is high. The energy source can be saved.

- Batch drying with different capacity available

The machine has low noise and stable operation. The temperature can be controlled automatically. The installation and maintenance are very convenient.

Contact us if you need more details on Oven. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hot Air Oven、Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Hot air circulation oven includes four parts: main chamber, recycle fan, heating system and control system. Materials will be put on the drying tray and be pushed into the drying chamber by trolley. Cold air will be heated to a certain temperature via heating device, under the working of recirculation fan, hot air recycles in chamber, thus drying purpose could be reached by fully contacting between hot air and material. During drying, humid air will be exhausted gradually through damp outlet. Meanwhile, fresh air will be supplemented. Temperature inside oven could be kept evenly by adjusting the angle of shutter, thus make sure the drying uniformity of material with equal rate.

Features

- Most of hot air is circled inside the oven. The hot efficiency is high. The energy source can be saved.

- Batch drying with different capacity available

The machine has low noise and stable operation. The temperature can be controlled automatically. The installation and maintenance are very convenient.

Contact us if you need more details on Oven. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hot Air Oven、Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Dryer Oven

Premium Related Products

Other Products

Hot Products

GMP Standard Tablet Coating Machine for PharmaceuticalRotary Tablet Press Machine (ZP-9) for PillStainless Steel Grinder/ Pin MillV Shape Mixer for Two Powder MaterialFluid Bed Granulating Machine for MedicineGMP Standard Stainless Steel Tray Drying MachineGlass Type Lab Scale Mini Spray DryerMc-1 Bag FilterJyg Paddle DryerSzg Cone Vacuum DryerZlg Vibration Fluid Bed DryerHyg Rotary DryerStainless Steel 304 Spin Flash Dryer for Chemical ProductLPG Centrifugal Spray DryerDw Belt DryerCT-C Hot Air Circulation Oven