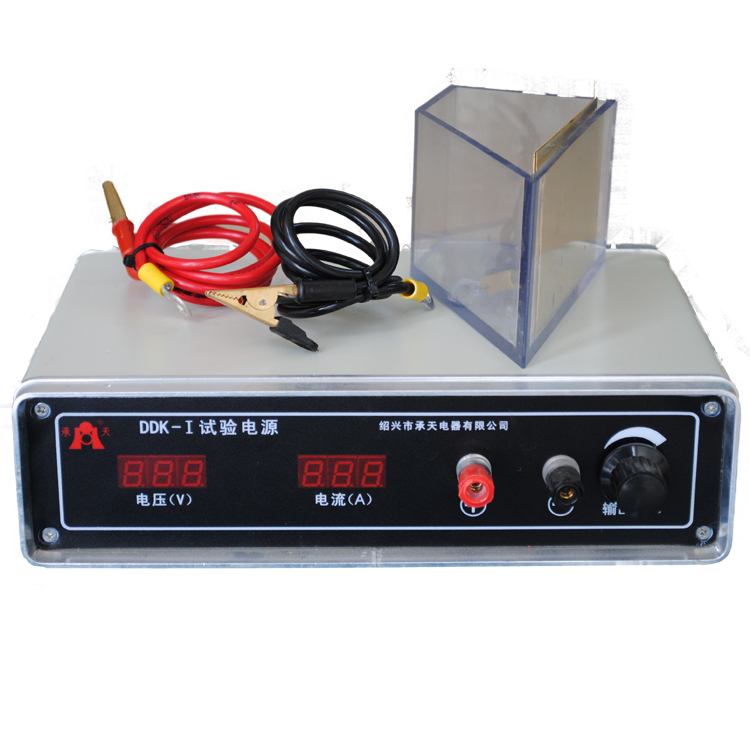

Plating test power supply

Basic Info

Model No.: DDK

Product Description

Thank you for you using our DDK series multifunction experiment power source, for keeping a good working state and making you operate this equipment correctly, please read this operation instruction carefully before operation.

DDK Series high accuracy multifunction experiment power source

1、Brief introduction

In order to acquire better plating coat, except selecting proper plating solution、reasonable technical arrangement, the strict monitoring means shall be adopted for process.

As an ideal equipment for monitoring plating solution, this experiment power source can be used for observing the surface state of plating coat, determine the brightness、smoothness、toughness and so on, specially for the control of additive content as well as the influence of impurity, even the current range.

With simplified operation and high degree of automation and less capacity requirements for solution, observe a wider current density range and the change of plating coat by one time experiment, additionally, confirm the approximately current density and other technologcial conditions(temperature and PH and alike). Thus, it is widely used for researching the main ingredients and the influence of additive for solution as well as fault cause proving, and used as the common equipment for tank liquor making、maintenance、correction and new technological test.

2、Main performance parameters

1、To run mode:CC/CV;

2、Automatic temp control:<60℃;

3、Air mixing:with small-size air Pump, the maximum air flow is160L/h;

4、Stepless voltage regulation:when under DC state,the output voltage is 0-12V;

5、 Timing alarm .

3、Working conditions

● Available standard:Enterprise Standard

● Power supply: 220V±10%、50HZ;

● Ambient temperature:-5℃~ +45℃;

● Installation site:less than1000maltitude,otherwise, reduce the capacity;

● Relative humidity : <85%;

● The equipment shall be placed at drying place with well-ventilation and there is no serious corrosive gas、dust and other explosive medium.

4、Method employed

1、Startup

● Turn the knob for adjusting potentimeter to maximum widdershins.

● Select waveform as required(turn the option switch to pulse or DC shift), then put through the power supply, open the start switch, the power indicator is on, then adjust the output potentiometer button till the voltage and current output has been up to the specified value.

2、Air agitation

When need air agitation, insert the rubber hose into plastic air-supply port of output end and hull cell, open air-supply switch for starting air pump.

3、Heating up

To heat Herman bath, you may connect plugs of Herman bath and Thermometer probe into the outlets in the rear panel, respectively. Thermometer is inserted into the suitable position in Herman bath. Turn the Temp. Adj. (Temperature Adjust) button clockwise to maximum position, and push Heat button to On position. The indicator for Heat will light. Herman bath will warm up soon. You need observe thermometer. When temperature of Herman bath to the value you need, turn Temp. Adj. button anti-clockwise until the indicator of Heat off. The temperature of Herman bath will automatically be adjusted to keep the original temperature.

5、Points for attention

● When arrival of goods, unpack the package to check if there is any damage、loosening and wetting in the process of transport, if any, remove the fault, then carry out other operation.

● With high frequency switching power supply, the shell of equipment can produce static( No harm to people) , so the equipment mast be connected with earth reliably .

● Before start the machine, both the voltage and temperature adjusting knobs shall be turned to maximum anticlockwise;

● The heating source in hell cell is internal heating 35W/220V iron core,if any damage, other model iron core can be used;

6、Packing list

1、Experiment power source 1

2、Ordinary hell cell 1

3、Standard hell cell 1

4、Thermometer 1

5、Operation instruction 1

7、Warranty

a、The user may get maintenance by warranty card or related technical contract under warranty.

b、The length of warranty for DDK-Ⅱexperient power source is one year,while the damage caused by the act of man,operation violated to working conditions,or wrong operation and bad maintenance is beyond the warranty range.

c、Attention in warranty:

1)、Our company shall be responsible for repair free for product quality problem, the man-made damage or fault is not included .

2)、For the damage caused by improper operation, our company shall provide maintenance with proper charge .

3)when contact us for solution, please tell us the equipment model、identification number and fault phenomenon and alike.

Product Categories : Switching Power Supply > Oxidation Switching Power Supply